In the world of food and beverage, wine holds a special place. It is a drink that has been enjoyed for centuries and is deeply intertwined with culture and tradition. Have you ever wondered about the process behind the creation of this delightful elixir? In this article, we will explore the fascinating journey of wine, from glass to vine. Join us as we delve into the details of the wine making process.

The Science of Wine

The scientific study of wine, has advanced our understanding of winemaking and wine appreciation. From the chemical composition of grapes to the sensory evaluation of wine, oenolists, vinitculturists and viticulturitists delve into the intricacies of this complex beverage. Scientific advancements continue to shape the industry, leading to innovations in vineyard management, fermentation techniques, and quality control.

Viticulture vs Viniculture

Viticulture and viniculture may sound similar, but they have a very important distinction between them. Viticulture is the broader cultivation and study of grapes for various purposes. It delves into the art of nurturing grapevines, understanding the climate, soil conditions, and vineyard management techniques.

On the other hand, viniculture focuses specifically on grape cultivation to make wine. It involves the meticulous selection of grape varieties and cultivation techniques aimed at maximizing wine quality. Viniculture zooms in on making sure the grapes are of the best quality to create exceptional vintages.

Viniculture vs Oenology

While viniculture focuses on the cultivation of grapes and the management of vineyards, oenology revolves around the science and art of winemaking. Oenologists oversee the fermentation process, where grape juice is converted into wine through the action of yeast. They decide on fermentation vessels, for example the type of barrels used for aging (e.g., oak) and the duration of aging to impart desired flavors and textures to the wine.

They also select the yeast strains, and fermentation temperatures to achieve specific flavor profiles. Part of that process is also overseeing the chemical composition of wine. This includes the blending of grape varieties, alcohol content, acidity, and tannin levels.

Understanding Grape Varieties

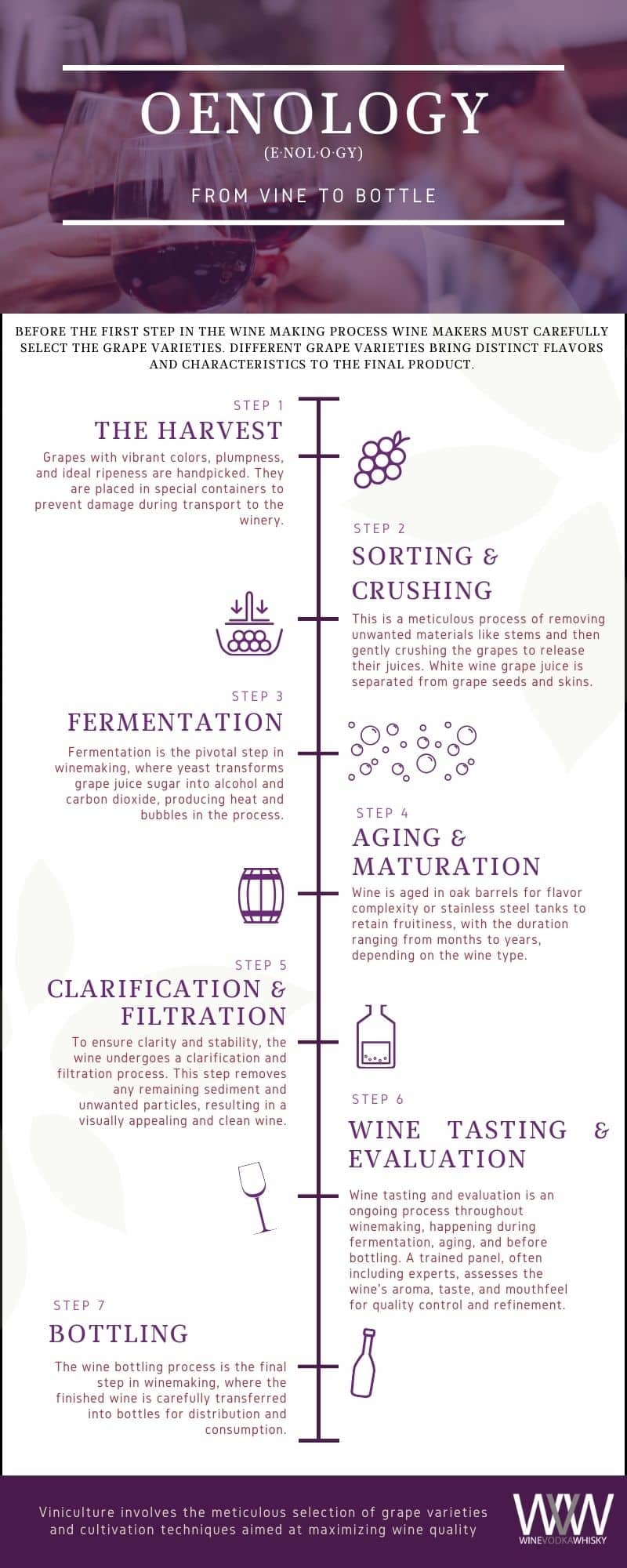

The first unofficial step in the wine making process is to carefully select the grape varieties. Different grape varieties bring distinct flavors and characteristics to the final product. Common grape varieties include Chardonnay, Cabernet Sauvignon, Merlot, and Pinot Noir.

Each variety has its own unique attributes that contribute to the complexity and taste of the wine. For instance, Cabernet Sauvignon grapes are known for their bold, robust flavors, while Chardonnay grapes can produce wines with a wide range of flavors, depending on factors like oak aging. The type of grape used in winemaking, coupled with the terroir, has a profound impact on the final product. Pinot Noir grapes, for instance, are highly sensitive to terroir, and their expression can vary dramatically from one vineyard to another.

What are the 7 Steps of the Wine Making Process?

Step 1: Harvesting the Grapes

Once the grape varieties are chosen, the first official step in the wine making process is harvesting the grapes just at the right moment. The timing of the grape harvest is a critical factor in determining the chemical composition of the grapes. It directly influences elements like sugar content, acidity and tannin levels .

- Sugar Content: As grapes ripen, their sugar level rises, this is important becuase the amount of sugar in the fruit impacts the alcohol level. A machine called a refractometer measures the sugar in a unit called “Brix” (Bx). To make sure the grapes are just right for picking, 3 to 4 weeks before the grapes are expected to be ripe, they are picked from different parts of the vineyard. Within the vinyard they take grapes from different rows, different parts of the grape cluster, and so on, and test their Brix. This helps them get a good idea of when the grapes will be ready to pick.

- Acidity: Grape acidity is crucial for wine freshness and balance. Harvesting too early can result in overly acidic grapes, while waiting too long may lead to low acidity, impacting the wine’s vibrancy and aging potential.

- Tannin Levels: Tannins, found in grape skins and seeds, contribute to a wine’s texture and aging ability. The timing of the harvest can influence the tannin structure, affecting the wine’s mouthfeel and overall quality.

How Are Grapes Harvested?

Harvesting by Hand

Until the 1950’s, grapes were all harvested by hand. Harvesters move carefully through the vine rows, inspecting the grape bunches one by one. They are looking for vibrent colors like deep purple or golden yellow. They feel the grape to make sure it it is plump and juicy, with a slightly soft and yielding texture when gently squeezed. In some cases they may also taste the grape to confirm the flavor profile.

Once selected, the bunches are detached from the vine, by hand or with small shears. The utmost care is taken to prevent bruising or damaging the grapes, as damaged fruit can negatively impact the wine’s quality. As the grapes are picked, they are carefully placed into baskets or bins. These containers are designed to prevent the grapes from getting crushed or bruised during transport from the vineyard to the winery.

Mechanical Harvesters

In the 1950’s and 60’s mechanical harvesters were invented. In the early days, the havesters were a bit hash on the grapes, but advancements in the technology have come a long way. Modern technology is both gentle and precise. Owners with the most advanced equipment are able to fine tune machines to selectively harvest only ripe fruit rather than picking every single grape. They can also detect grape clusters from mud, leaves and other particles.

The machine generally works by beating the vine with rubber sticks so that the fruit drops onto a conveyor belt, which brings the fruit to a bin. The The material other than grapes (MOG) was sucked off by large fans. Some of the havesters till have a hard time telling the difference between ripe, healthy grapes and unripe bunches. In this case, the grapes still need to be sorted out at the facility.

The biggest benefit of the mechanical harvesters is their speed. The machines can process up to two acres per hour!, that is up to 200 tons of grapes per day! To hand pick the grapes, it can take 20 to 30 skilled havesters an hour to do a single acre.

Acceptance of Mechanical Harvesters

Decades ago, due to massive labor shortages, Australia was the first major market to accept mechanical harvesters. Since then the industry has seen steady intrest and transition to the innovation. By some estimates, 90 to 95 percent of Washington vineyards are machine-harvested. One of the slowest areas to adapt are Sonoma and Napa counties. But even there, some of the larger vineyards are now moving towards 50 percent mechanical, if not more.

When is harvest season?

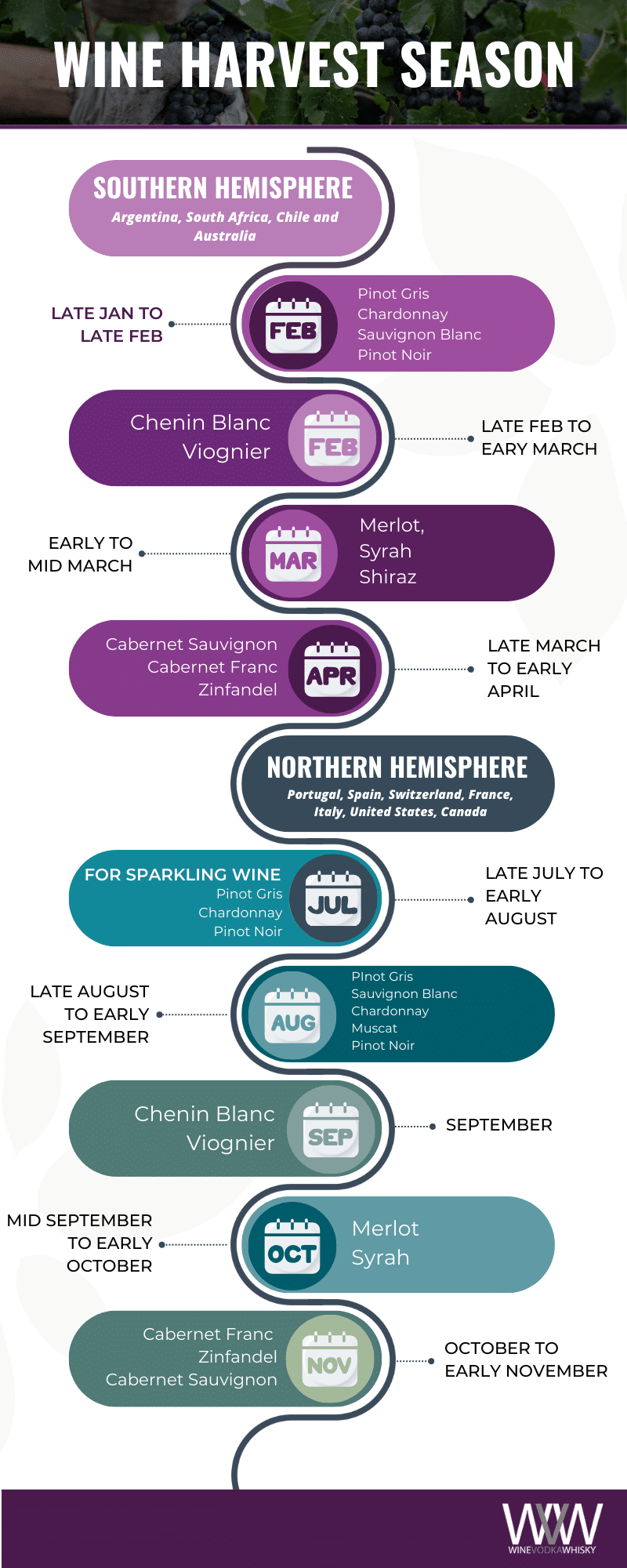

Harvest season spans a period of about two months. Diufferent grapes are garvested during different times in that two month period. In the Northern Hemisphere (California, Italy etc), harvest season is from August to October. In the Southern Hemisphere, the harvest season is from February to April.

Step 2: Sorting and Crushing

After the grapes are harvested, they undergo a meticulous sorting process to remove any unwanted materials. This ensures that only the best grapes make their way into the wine production.

- Sorting the Grapes: After the grapes have been picked, the next crucial step is sorting. During this process, workers or machines inspect the grapes closely to ensure that only the ripe ones are used. Any leaves, stems, or unripe or damaged grapes are removed.

- Gentle Crushing: Once the grapes have been sorted, it’s time to extract the juice. The grapes are gently crushed to release the liquid. The goal is to extract the juice without damaging the seeds or grape skins. If the skins are dampaged they can add unwanted bitterness to the wine.

- Separation for White Wine: For white wine production, the process takes a different turn at this point. After crushing, the juice is immediately separated from the grape skins and seeds. This is because the color and tannins in white wine come mainly from the grape skins. By separating them early, white wines maintain their characteristic light and clear appearance.

- Contact for Red Wine: In contrast, red wine production involves keeping the grape skins in contact with the juice during fermentation. This extended skin contact is where the magic happens. The skins impart color, flavor, and tannins to the wine.

Step 3: Wine Fermentation, The Magic Begins

Fermentation is the most crucial phase of the wine making process. During fermentation, yeast converts the sugar in the grape juice into alcohol and carbon dioxide. During this stage, yeast consumes the natural sugars in the grape juice and converts them into alcohol and carbon dioxide. This process generates heat and causes the juice to bubble and froth.

How Long Does Wine Take to Ferment?

The time it takes for wine to ferment can vary widely depending on several factors including

- The type of wine being made. Grapes with high sugar content may take longer to ferment.

- The specific yeast strains used (some ferment faster than others).

- And the winemaker’s goals. Some wines, like light white wines, may benefit from shorter fermentation to preserve fresh fruit flavors. Red wines, on the other hand, may undergo longer fermentation for color extraction and tannin development.

Generally speaking though, the process can take anywhere from a few days to several weeks.

Wine Fermentation Temperaure

The temperature, yeast selection, and duration of fermentation greatly influence the wine’s flavor profile and aroma.

When fermentation occurs at lower temperatures (55-70°F), it tends to be slower and more gradual. This is often preferred for white wines, as it can help preserve delicate fruit flavors and floral aromas. Cooler temperatures also retain higher acidity, which contributes to freshness and balance in the wine.

Warmer fermentation temperatures (70-85°F) speeds up the process. This is commonly used when making red wine where winemakers want to extract color, tannins, and complexity from the grape skins. Higher temperatures can enhance the development of more robust and intense flavors. However, excessive heat during fermentation can spoil the wine.

Also important to the process is the type of yeast. Native, or wild yeasts can be found on the grape skins or in the winery environment. These yeasts can add to a sense of terroir. However, they can also be unpredictable and may result in longer, less controlled fermentations.

A second option would be to use cultured yeasts specifically cultivated for winemaking. Winemakers can choose strains that emphasize certain flavor and aroma profiles. For example, some yeast strains enhance fruity notes, while others emphasize spice or floral qualities.

How to Stop Wine Fermentation

Typically, wine fermentation will stop on its own once the sugars in the wine have been consumed by the yeast. If the fermentation process has to be stopped for some reason, the easiest solution is to chill the wine to 40°F.

Step 4: Aging and Maturation

After fermentation, the wine is transferred to oak barrels or stainless steel tanks for aging and maturation. Aging allows the wine to develop complexity and depth. Oak barrels infuse flavors and aromas such as vanilla, spice, and toast, while stainless steel tanks preserve the wine’s natural fruitiness. The duration of aging varies, ranging from a few months to several years, depending on the type of wine.

Wine Aged in Oak Barrels

Oak enhances the flavor of wine through a combination of chemical and physical interactions between the wine and the wood. The oak releaes compounds like vanillin, which adds sweetness, and lactones, which contribute coconut and creamy notes. It allows controlled oxygen exposure which softens tannins (tannins are a natural compound found in grape skins, seeds, and oak barrels. Tannins are responsible for the dry feeling when you taste the wine ).

The oak can also remove unwanted elements like sulfur compounds, which can cause off-flavors. It also extracts smoky and toasty notes. The specific oak type influences flavor (French for subtle vanilla, American for stronger vanilla and coconut). Oak-aged wines often have better aging potential, as the slow maturation process in the barrels can help the wine evolve and improve for many years, even decades. Winemakers can use the barrel to customize the process for unique profiles.

Bourbon Barrel Aged Wine

A bourbon barrel is made from new American white oak. It’s constructed from new American white oak. Aging wine in a Bourbon barrel is distinct from other oak barrels due to its previous use in making Bourbon and becuase Bourbon barrels are charred before making the Bourbon. The wine can absorb the residual Bourbon flavors, such as vanilla, caramel, and smoky notes and also have a more pronounced sweetness.

In other words, wine aged in a Bourbon barrel will likely have a more pronounced influence of Bourbon-related flavors, while wine aged in a traditional oak barrel aims to complement the wine’s existing qualities with a subtler oak presence.

Wine Aged in Whiskey Barrels

Just like Bourbon barrels, Whiskey barrels are made from oak, and can influcience the taste of wine by infusing distinctive flavors to the wine, including notes of vanilla, caramel, and smokiness. They can also introduce a sweetness to the wine that comes from the residual sugars from the whiskey. Aromas like toffee, butterscotch, and charred oak are commonly associated with wine aged in whiskey barrels.

When comparing it to wine aged in a Bourbon barrel, the influence of whiskey barrel aging on the wine is typically less intense compared to the bold flavors associated with bourbon.. Using whiskey barrels for wine aging is also a relatively newer trend in winemaking.

Aging Wine in Stainless Steel

One of the primary benefits of using stainless steel is that it preserves the wine’s primary fruit characteristics. Unlike oak aging, stainless steel does not impart any additional flavors or aromas to the wine, allowing the natural grape flavors to shine. It also allows winemakers to have precise control over fermentation and aging conditions, preventing unwanted influences on the wine. Stainless steel also reduces oxygen exposure, making it ideal for wines that require minimal oxidation, such as white wines. Lastly, it provides a cost efficient and sustainable alternative to oak aging (oak barrels do need to be replaced every three years).

How Many Wine Bottles are in a Barrel?

A standard wine barrel typically holds around 59.2 gallons or 225 liters of wine. This is equivalent to approximately 300 bottles of wine, assuming each bottle contains the standard 750 milliliters.

Step 5: Wine Filtration and Clarification

To ensure clarity and stability, the wine undergoes a clarification and filtration process. This step removes any remaining sediment and unwanted particles, resulting in a visually appealing and clean wine. Various methods such as fining and filtration are employed to achieve this clarity without compromising the wine’s taste and aroma.

Before filtration, the wine undergoes a processes called racking. During this time, the clear wine is separated from any sediment or solids that may have settled at the bottom of the barrel or tank. This initial step helps remove larger unwanted particles. Next, the wine might go through something called “settling and cold stabilization.” This means the wine is chilled really cold to make tiny crystals form from a certain type of acid in the wine. These crystals can make the wine look cloudy, so the cold helps get rid of them. This can take a few weeks.

How is Wine Filtered?

Wine is filtered through a process that involves passing the wine through various types of filters to remove unwanted particles and substances. It’s important to filter the wine not only to make it visually clear and appealing to consumers but to also make the wine stable by removing microorganisms and proteins that could cause haziness, off-flavors, or spoilage.

There are multiple steps to the filtration and clarification process.

- Pre-Filtration: This is the initial step in the filtration process. Coarse or big filters are used to remove larger particles, such as grape skins, yeast cells, and other solids. This step helps prevent clogging of finer filters.

- Fine Filtration: After pre-filtration, the wine undergoes fine filtration. In this stage, the wine is passed through filter pads with smaller pore sizes. These finer filters can remove smaller particles and microorganisms that are not caught by the pre-filters.

- Cross Flow Filtration: In some cases, winemakers use cross-flow filtration. In traditional filtration, where wine is pushed directly through the filter, solids can accumulate on the filter surface, causing clogs and reducing the filtration efficiency. Cross flow filtration minimizes clogging because it constantly sweeps away the solids from the filter surface, allowing the process to continue smoothly. This results in superior clarity.

- Sterile Filtration: Sterile filtration is a critical final step to ensure the wine is free from any remaining yeast or bacteria that could cause re-fermentation or spoilage. In this stage, very fine filters with pore sizes of 0.45 microns or smaller are used to make the wine microbiologically stable.

Step 6: Wine Tasting and Evaluation

Wine tasting and evaluation is not a linear step in the wine making process, it is an activity that happens across many steps of the wine making process including fermentation, maceration, aging, and before bottling. A trained panel of tasters, often including the winemaker, viticulturist, and other experts, systematically evaluate the wine’s sensory attributes. These attributes include aroma, taste, and mouthfeel.

- Aroma Assessment: Tasters check how the wine smells. They see how strong the smell is, how complex it is (if there are many different scents), and what specific things they can smell, like fruits, flowers, herbs, or anything that might not smell good.

- Taste Evaluation: Tasters taste the wine to figure out what it tastes like. They think about how sweet or sour it is, how much tannin it has (like the feeling of dryness in your mouth), how heavy or light it feels, and if everything tastes balanced and right for that kind of wine.

- Mouthfeel: Tasters see how the wine feels in their mouth. They consider things like how thick or thin it is, and how long the flavors stick around on their tongue. They also notice if it feels smooth or makes their mouth feel dry.

Winemakers then identify and address any flaws or faults in the wine and make adjustments as needed. This process helps determine the wine’s readiness for bottling. Tasting notes and scores are often provided from this step to guide consumers in their selection.

Step 7: Bottling the Wine

Finally, we are at the last step of the wine making process. Before the actual bottling begins, the winery preps all its materieals and typically sanitizes the bottles to prevent contamination. From there, the process carefully begins:

- Nitrogen Injection: Nitrogen is injected into each bottle to displace oxygen. This step helps prevent oxidation, which can negatively impact the wine’s quality and shelf life.

- Filling: The machine is programmed to fill each bottle with a precise amount of wine. The wine is pumped or gravity fed into the bottles, and it’s essential to ensure consistent fill levels.

- Corking or Capping: Once filled, the bottles move to the corking or capping station. The machine securely seals the bottles with corks or alternative closures, such as screw caps.

- Labeling: Labels are automatically applied to the bottles, providing essential information about the wine, such as the vintage, winery, varietal, and legal designations.

- Capsules or Foils: Capsules or foils are placed over the bottle neck and closure to protect against tampering and dust.

After wine bottling, quality control checks ensure proper sealing and accurate label application. Bottles are then packaged for distribution, often in protective cases or boxes. Wine may be stored briefly to recover from potential disturbances during bottling, contributing to its stability. Once ready for market, wine is distributed to various channels, including retailers, restaurants, and directly to consumers.

How Many Bottles of Wine Are Bottled Each Year?

This number will change from year to year, but in 2022, approximately 34 billion bottles of wine were bottled globally. In 2022, global wine production amounted to about 258 million hectoliters. One hectoliter is 26.4 gallons, so global production was 6.8 billion gallons. One gallon is aproximately 5 bottles of wine. 6.8B x 5 = 34B!

Storing and Cellaring

For wine enthusiasts, proper storage and cellaring are essential. Wine should be stored in a cool, dark place with a constant temperature and humidity level. This allows the wine to age gracefully and develop complex flavors over time. Some wines benefit from cellaring for several years, while others are meant to be consumed relatively young. Here are a few tips:

- Temperature: Wine should be stored at a consistent and moderate temperature, typically between 45-65°F (7-18°C). Fluctuations in temperature can damage the wine, so it’s important to avoid extreme heat or cold.

- Humidity: Relative humidity levels of around 70-75% are ideal for wine storage. This helps keep the corks from drying out and ensures a proper seal, preventing oxygen from entering the bottle.

- Darkness: Wine is sensitive to light, especially ultraviolet (UV) light, which can cause spoilage. Bottles should be stored in a dark or dimly lit environment, away from direct sunlight.

- Vibration: Wine doesn’t like vibrations, as they can disrupt the aging process and cause sediment to remain in suspension. Store wine in a place where it won’t be subject to constant movement or shaking.

- Horizontal Storage: Wine bottles with natural corks are best stored horizontally. This keeps the cork moist, preventing it from drying out and allowing air to seep into the bottle.

- Ventilation: The storage area should have good ventilation to prevent musty odors or mold from affecting the wine. Avoid storing wine in a place with strong odors, as wine can absorb scents from its environment.

FAQs About the Wine Making Process

How Many Grape Varieties Are Used in Winemaking?

There are thousands of grape varieties used in winemaking, but some of the most well known and widely planted include Chardonnay, Cabernet Sauvignon, Merlot, Pinot Noir, Sauvignon Blanc, and Syrah.

Chardonnay was the most crushed grape variety in Californian wine production in 2022, accounting for 14.4%.

How Long Can Wine Be Stored?

The storage life of wine depends on various factors, including the type of wine, its quality, and the storage conditions. In general, most wines are meant to be consumed within a few years of their vintage, while certain high-quality wines can improve with age and be enjoyed for decades.

Do Wines Get Better With Age?

Not all wines improve with age. While some wines, such as Bordeaux, Barolo, and vintage Port, can benefit from aging, the majority of wines are meant to be consumed within a few years of their release. Aging can soften tannins and add complexity to certain wines, but it can also result in the wine losing its fruitiness and becoming less enjoyable. It’s important to research the specific wine you have in mind to determine if it is suitable for aging.

Does Wine Age in The Bottle?

Yes, wine can age in the bottle.